Critical's Race to Power America

On the team building a universal interface between heat and power.

In early August, inside a nondescript warehouse on the industrial edge of Los Angeles, Spencer Jackson and his team spun up a power plant. It was a compact 50-kilowatt turbine rig, packed into a shipping container, that they designed and built from scratch. Perhaps more of a power seed than a plant, the unit could power little more than their building, yet the achievement was enormous. It was proof that Critical could compress the hardware required for power generation into a module that could be manufactured at scale, and shipped out like any other industrial product.

It’s important to note that this is not how America builds energy infrastructure. Things are typically made custom, welded and assembled on-site, with years between starting a project and actually bringing it online. Critical’s approach is a significant technological solution to one of America’s largest economic and political challenges, namely our inability to get more electrons flowing across the country. Simply put, we’re running into a wall on power. With urban population growth, the re-emergence of our industrial ambitions, and recent enthusiasm around electrifying large swaths of our activities, from transportation via electric vehicles to heating our homes with electric furnaces, the demand curve has bent sharply upward. However, the grid is nowhere near capable of actually servicing all of it. “If we wanted to electrify the whole country, we would need to triple our energy generating capacity,” Spencer says. It’s a thought that weighs on him, because that figure doesn’t even factor in the surge of demand from hyper-scalers and data centers.

America hasn’t built out generating capacity at this scale in decades. The last such notable build out happened seventy years ago during the nuclear boom. Today, the situation is actually the reverse. Our aging power generation infrastructure is retiring faster than new capacity can replace it, and over the intervening decades, much of the domestic hardware production that supported a growing energy industry has shuttered. As a result, the consequences are mounting. Residential electricity prices are ticking upward. Grid operators are telling new data centers and industrial projects that they’ll connect them, but only as “non-capacity backed load,” meaning their power can be cut at any time if the grid gets stressed. All this is happening at a time when China is blanketing itself in solar panels whose total power output will soon rival that of the entire United States.

The contrast has been hard to ignore, particularly for Spencer. Two years ago, as he was wrapping up his seventh year at SpaceX working on the company’s Falcon Heavy, Starship, and Raptor engines, it dawned on him that if the United States had resurrected the stagnant space industry through SpaceX, why couldn’t it do the same for power generation? After all, what is a power plant if not a rocket engine’s humbler cousin, designed for generating electricity instead of thrust?

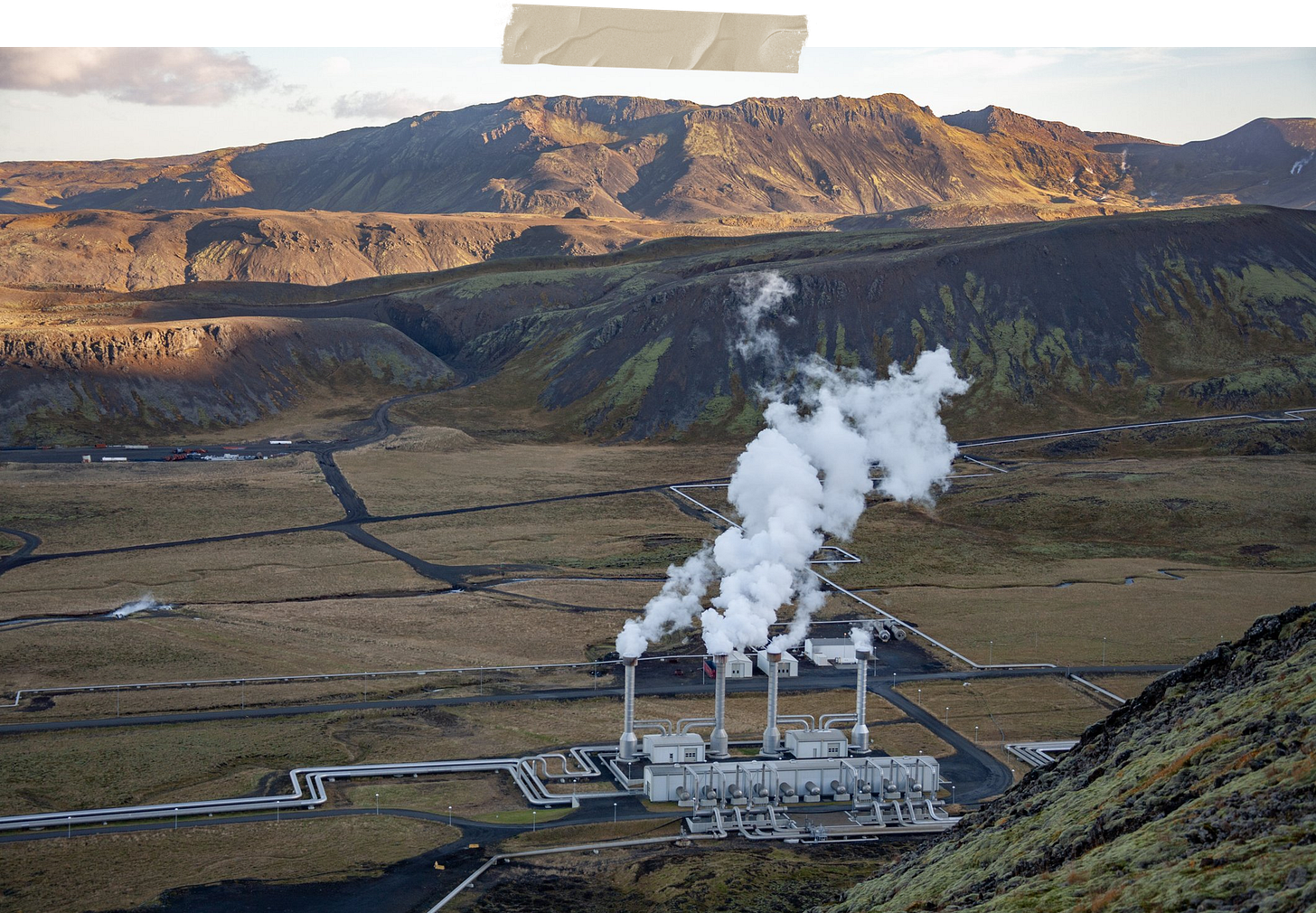

That same year, a first-of-its-kind breakthrough showed what such a revival might look like. In Nevada, Houston-based Fervo Energy drilled the first horizontal wells for geothermal power in US history. Until then, commercial geothermal projects had been confined to very rare geographies where volcanic heat conveniently vented to the surface.

Iceland is the classic example. A third of its electricity comes from geothermal, or, hydrothermal power, thanks to a landscape riddled with vents, geysers, and steam fields. If you have boiling water erupting from the ground, you can just pipe it into a turbine, spin a dynamo, and get free electricity. California has its own taste of this at The Geysers, a cluster of steam reservoirs 70 miles north of San Francisco that together generate more than 700 megawatts. It’s actually the largest geothermal complex on Earth, yet it only supplies about 2% of California’s power.

For decades, the full potential of geothermal had been constrained by our inability to efficiently access the Earth’s subterranean heat, leaving us reliant on locations where that heat delivered itself to the surface. Horizontal drilling changed the calculus on that completely.

Underground temperatures rise by roughly 25-30°C for every kilometer you drill. Go deep enough, and you quickly hit the boiling point of water or beyond. Now imagine drilling straight down, then bending the well laterally to run through hot rock like a buried radiator. You’ve turned the subsurface into an engineered heat exchanger, or what the geothermal community calls an ‘enhanced geothermal system’.

The ability to drill horizontally is the same technique that unleashed America’s shale boom, by allowing operators to fracture long slats of shale and liberate isolated pockets of natural gas from the deep subsurface. Now that expertise, refined over decades, puts geothermal on a technology curve of its own, transforming what was once a niche resource into an energy source that can scale almost anywhere. Don’t ever say the oil and gas industry hasn’t done anything for renewables.

When Fervo’s Project Red demonstrated the first functional-scale enhanced geothermal system in the United States, it ignited a fire in the energy community. Now there was a way to access a free and essentially inexhaustible energy resource that, according to estimates by the Department of Energy, could ultimately supply America’s current electricity consumption many times over.

Until then, the industry’s attention had been focused on the subsurface, fixated on how to drill deeper or fracture through tricky rock, while the machinery actually responsible for turning the hot water into power sat woefully neglected. After attending a conference on the burgeoning geothermal industry, Spencer came away with a clear conclusion, “Everyone there was working on the subsurface. Every single one. Nobody was thinking about turbomachinery. That world just doesn’t have the skillset.”

This resulted in a situation where a new geothermal site could be drilled and ready in as little as 17 days, while the power plant hardware, the actual generator, would take another two years to be developed and installed at a cost of half the entire project.

Regarding power generation, Spencer explains that “a lot of the geothermal guys assume they can just buy something off the shelf. The truth is, the off-the-shelf turbines are built for gas, coal, or nuclear. They’re the wrong machines for the job.”

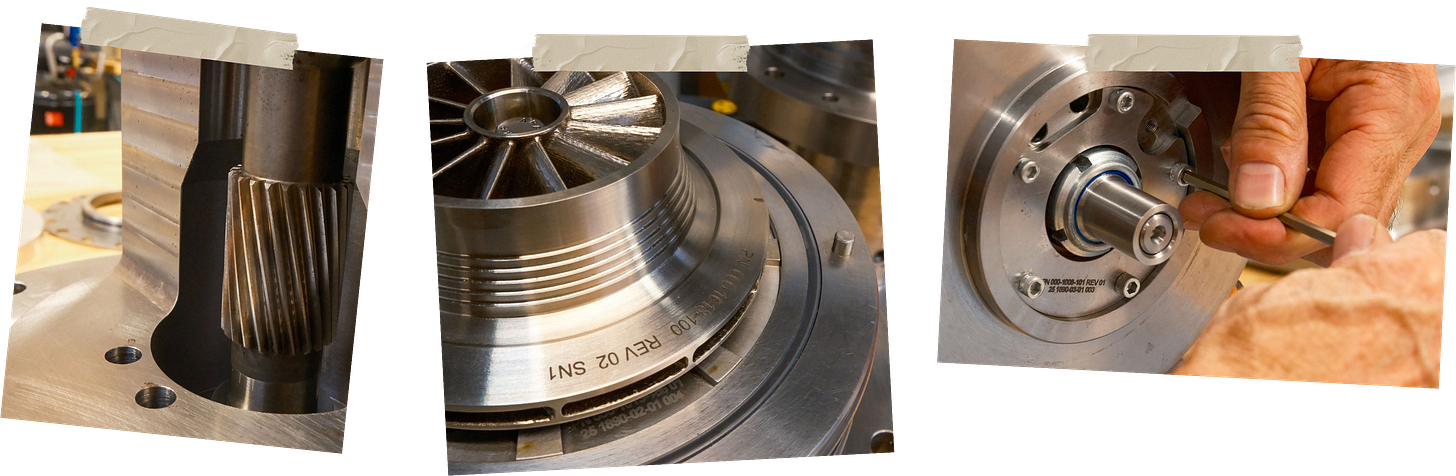

Geothermal demands a unique kind of turbine. Gas turbines run on combustion gases reaching anywhere between 1000-1500°C. Coal or nuclear power plants use high-pressure steam that hits between 500-600°C. Geothermal, by contrast, deals with gentler heat. Temperatures regularly stay around 200°C. If you run cooler steam through a turbine designed for a gas plant, the machine will badly underperform. The blades won’t extract as much energy, conversion efficiency will plunge, and suddenly a huge share of the heat extracted from the Earth will be wasted. In an industry where every point of efficiency is another megawatt you can sell, that’s a devastating blow.

To operate efficiently, geothermal’s power generation has to follow specialized designs, but the big players, like Siemens or GE, aren’t building them. Their focus is on gas turbines, where the market is established and the margins are proven. Until now, that’s left the field confined to a few specialists like Turboden, a subsidiary of Mitsubishi, Baker Hughes, and Ormat, which have built plants for decades. All have delivered in the past, but only on the slow, capital-heavy timelines of entrenched incumbents. In an industry that now needs speed, their model is becoming more and more of a bottleneck.

Exquisite custom builds would have to give way to a process that could deliver scale through mass manufacturability. It was the same kind of insight that led to the establishment of SpaceX nearly twenty years ago, and it was, in large part, Spencer’s years of experience there that gave him the confidence that he could be the one to make it real. “If we could put a 40MW turbopump into a rocket, we could damn well fit a two-megawatt generator inside a shipping container,” he told me.

So, what’s the fastest way to get power generation up and running? Spencer’s answer was to toss out everything that incumbents were doing. No more hauling heavy parts to a site, welding, bolting and constructing everything on prem. The idea was to flip the script and make the site a place for final delivery only. Critical’s plant gets built in his factory, shipped whole, and plugged in on a customer’s site.

It’s understandable, however, why this principle wasn’t shared by incumbents. Building small turbines is brutally hard. At larger scales, the engineering is more forgiving. A thousandth-of-an-inch gap at the edge of a big turbine hardly matters. At small scales, that same gap can bleed away a significant portion of your energy. The geometry works against you too. Large turbines can stack rows of blades into multiple stages, like the inside of a jet engine, extracting every last bit of energy. Small turbines don’t have that luxury, so they’re often forced to make do with just one or two stages. The smaller you go, the tighter the tolerances, the harsher the tradeoffs, and the closer your design has to be to perfect.

That’s why to prove that Critical could actually make this work, they started with a really small turbine — a 50 kilowatt benchtop unit. It was just big enough to prove their system could work, while being small enough to let them iterate quickly and feel comfortable that by nailing the fundamentals at small scale, they could graduate to a larger build with relative ease.

Then came the proof point. It took a year of designing proprietary parts, months of waiting out lead times, and more than a few hard resets on components that had to be rethought from scratch. In August, Critical successfully spun their turbine, and the loop held. It was only 50 kilowatts, but that was enough to offer a glimpse at what a new generation of energy infrastructure might look like in America.

In the two years since Fervo’s Project Red came online in Nevada, excitement around geothermal has only intensified. What began as a 3.5MW pilot is now being expanded into Corsac Station, a 115MW facility built to serve corporate giants like Google, which has already signed on through a 20 year power purchase agreement. Even bigger plans are underway in Utah, where Fervo’s Cape Station is slated to produce 100 MW by 2026 and scale to 400 MW by 2028. Cape Station, however, has already been permitted for nearly 2 GW of capacity, a scale that would make it one of the largest clean power projects in the country.

Google isn’t the only hyperscaler now turning to geothermal. Meta recently signed a deal with XGS Energy for a 150MW project in New Mexico to support its local data centers, and in the preceding few months, Washington has stepped in too, introducing emergency permitting procedures to expedite review of new geothermal projects, signaling the intention to make this resource a pillar of the nation’s new energy buildout.

Projects that start small soon expand to chase industrial scale, all while leaving little trace above ground. A single site can quietly deliver gigawatt-years of electricity without blanketing the horizon in panels or turbines, making it one of the only resources physically capable of matching industrial demand.

This is where Critical sees its opportunity. Its next goal is to scale the 50 kilowatt turbine into a 2-megawatt modular unit, turning power generation equipment into plug-and-play building blocks for geothermal farms. By Critical’s estimates, such a unit could be assembled in-house and deployed in as little as 14 days. Developers could order a palette of turbines and stack them like servers in a rack, scaling generation in sync with the project’s scope. This is the benefit of modularity. As Spencer puts it, “In the past, every geothermal project was a one-off. You’d spend years just negotiating the design, then wait even longer for someone to build it. We make the product the same way every time, and if you need more power, you just add more modules.” For Critical, that means every geothermal project in development is on the drawing board.

But speed isn’t the only objective. Cost is another unlock here. Today, geothermal comes in at about $69 per megawatt-hour. That’s competitive with renewables, but pricey compared with natural gas. Critical believes its modular turbines can drive that number down to around $40 per megawatt-hour.

That difference would not only make geothermal cheaper than gas, broadly one of America’s lowest-cost power sources, but it would also expand the map. Critical’s technology wouldn’t just accelerate the projects already on the books, it would expand the frontier of geothermal itself, making viable a whole class of power plants that used to only exist in theory. It’s worth noting that for Critical, geothermal is just the beginning. The same compact, factory-built turbines that convert the Earth’s heat into electricity can do the same for other untapped sources too, like industrial waste streams or advanced nuclear plants. The long term ambition is to become a universal interface between heat and power, and in that vision, geothermal isn’t the endgame, but an important proving ground which will no doubt transform the composition of American baseload power.

At the end of the day, the grid needs dispatchable power. We’re steadily moving toward a future dominated by cheap solar, but intermittent resources alone won’t keep the lights on. Something needs to step in when the sun goes down. Nuclear once played that role, but spiraling costs and decades-long timelines have sidelined it. Geothermal, when unlocked at scale, can fill the gap. With horizontal drilling, it’s no longer confined to volcanic hotspots. It can be tapped almost anywhere. That makes it a uniquely flexible baseload, able to hum steadily alongside renewables or surge when the grid calls.

What’s more humbling to think about are the global implications of unlocking such an energy resource. For the first time in history, access to energy wouldn’t be dictated by geography or fossil reserves, but by who can drill and build the fastest. That flips the script on more than a century of geopolitics, where power was determined by coal seams, oil fields, and gas pipelines. Enhanced geothermal could mark the next wave, a universal and inexhaustible resource beneath our feet.

The question is no longer who has energy but who can scale it fastest. That is the race Critical was built to win.

The gas turbine supply chain is already onshore. GE Vernova makes them in Greenville SC. Modular turbines sound pretty cool though.